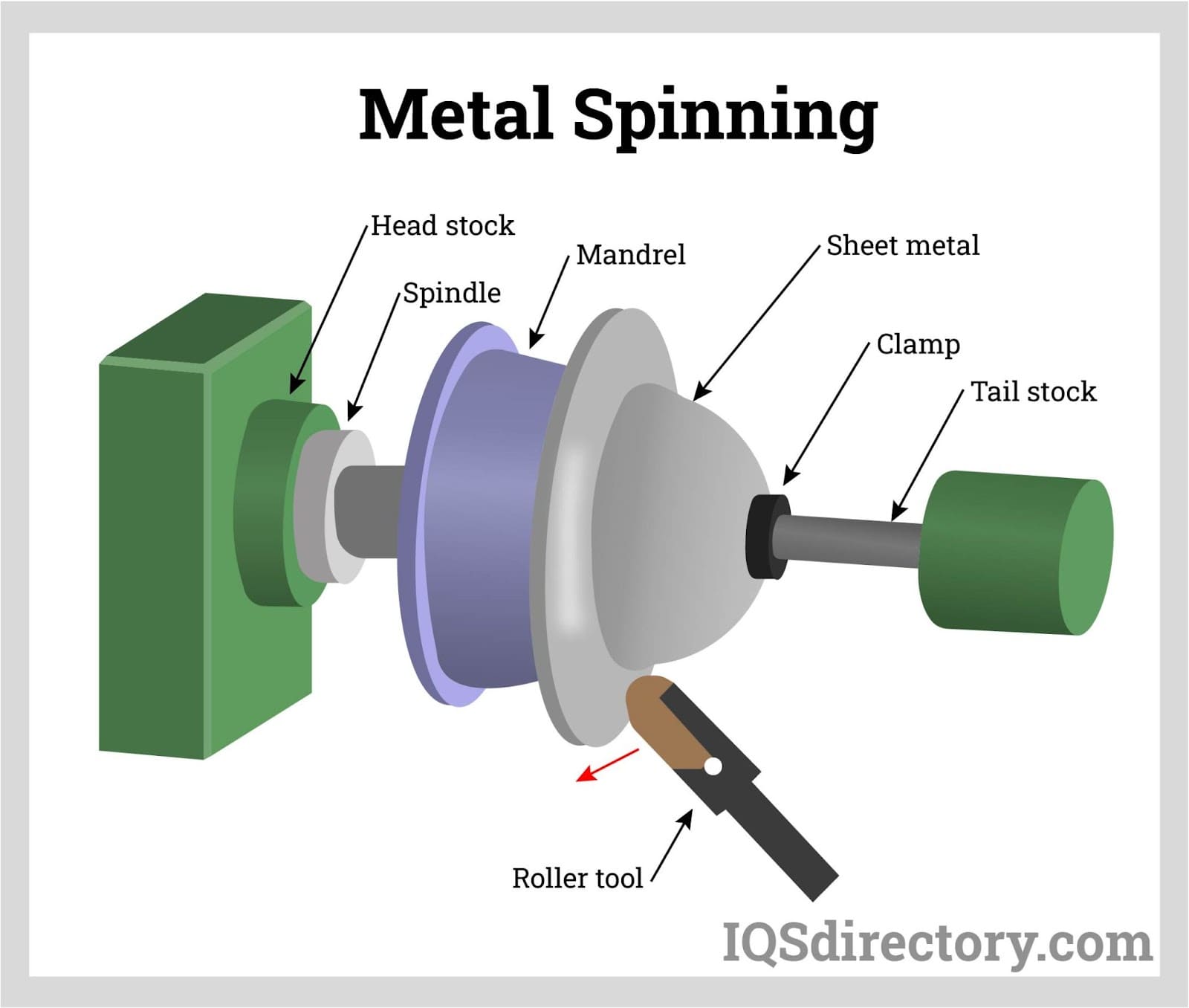

Metal spinning is a technique for creating rotationally symmetrical sheet metal pieces. The sheet metal discs spin while being shaped into hollow, rotationally symmetrical shapes. The spinning machine’s main drive rotates the blank, fixed between its shaped spinning mandrel and tailstock. Together, the mandrel and metal disc come into contact with the workpiece’s outer face through the spinning roller. The workpiece will take shape as the roller gradually shapes the material over predetermined passes. Read More…

At Ace Metal Spinning, we believe in creating products that precisely meet our customers' specifications. If you need a unique part, we can make it for you. We also provide in-house tooling to keep your costs low. It is our goal to benefit our customers however we can through our service, products, and prices. Learn more on our website today!

At Stuecklen Manufacturing Company, we take pride in our long-standing expertise in the art and science of metal spinning. Since our founding, we have dedicated ourselves to combining traditional craftsmanship with modern technology to produce precision-formed components that meet the highest standards of quality and performance.

At Sundry Metal Spinning, we specialize in providing comprehensive solutions for metal spinning, catering to the diverse needs of industries worldwide. With our commitment to excellence and extensive experience, we have established ourselves as a trusted partner for customers seeking high-quality and precise metal spinning services. Our metal spinning capabilities encompass a wide range of...

In business since 1944, Muncie Metal Spinning has been a metal spinning company offering tanks, air cleaners, sump breather tanks, fill cans and much more. In addition, we do custom ornamental metal spinning from aluminum, copper or brass, welding, shearing, and prototype development. Call us today for more information or visit our website and request a quote!

More Sheet Metal Spinning Companies

Sheet metal spinning can create many hollow components without sacrificing important advantages of metal shaping. In addition, the same metal spinning may integrate other processes. Metal spinning can also be referred to as metal forming.

How Metal Spinning Functions

Spinning is a fairly easy operation. First, a formed block is installed in a lathe's drive section—a pressure pad attached to the tailstock clamps a pre-sized metal disk against the block. The workpiece and block are then both rapidly turned together. The workpiece is then subjected to a localized force that moves over the block. A variety of lever tools are used to apply the force. Simple workpieces can be taken out of the block; however, more complicated designs need a multi-piece block. It is possible to spin intricate designs over ice formations, which melt away after spinning.

Types of Sheet Metal Spinning

Hot Spinning

During hot spinning, a heating torch raises the workpiece's temperature to the forging temperature. The workpiece is forced over the mandrel while the heating torch is pointed at it. This process is best when the material has poor ductility, or the metal sheet is too difficult to deform at room temperature. Any sheet metal can be spun at room temperature, often known as "cold spinning." The workpiece is already deformed due to its plastic condition, hot spinning causes significant distortion and refines the grain structure, which leads to better physical qualities like higher strength. But the metal that has been heated quickly oxidizes. The entire process is more expensive and challenging to manage.

Shear spinning

Shear spinning is also known as ‘power spinning’. When shear spinning, the workpiece slides along the mandrel's contour under the force of the rollers. Although the final part's material thickness is lower than in its initial blank form, its diameter doesn't change. Additionally, the work piece's depth rises. Since the workpiece is subjected to stronger compressive forces, its mechanical characteristics, are improved. Shear spinning influences the component's dimensional accuracy and surface finish, necessitating a more robust tooling design and accurate machining control. More friction is applied to the workpiece, which wears down the mandrel. Since this procedure produces a lot of heat, coolant is required.

Tube Spinning

A type of shear spinning known as "tube spinning" is used to lengthen and thin out hollow cylindrical tubes. The tube is initially positioned into the mandrel and clamped. Then, three or more rollers positioned evenly around the tube are used to draw the tube over the length of the mandrel. The axial flow of material follows a path comparable to the path taken by the rollers. Either inside the mandrel or outside, tubes can be spun. The tube is stretched over the outside of the mandrel during external tube spinning. Internal tube spinning involves stretching and spinning the tube inside a hollow mandrel.

Benefits of Sheet Metal Spinning

- In comparison to forging, stamping, casting, etc., the metal spinning method is thought to use materials more sparingly and produces less waste.

- Low tooling costs are possible because tools can be made to last for as long as the job function for which they are intended.

- Sheet metal spinning is significantly less expensive than traditional casting and stamping because of how specific the tooling is.

- In keeping with the previous benefit, it is simple to make design changes, making selecting metal spinning significantly more affordable. The supplier frequently discovers that customers want to alter and shrink a component during product development. By lowering the Tool size internally, there is no need to start over, saving time and money.

- Sheet metal spinning can be done acts quickly. Small to medium batch numbers can be manufactured in a few days because of the short lead times.

- Multiple passes over the material during the metal spinning process are also advantageous. This is due to the materials produced being hardened.

Choosing the Proper Sheet Metal Spinning Company

To make sure you have the most positive outcome when purchasing Sheet Metal Spinning from a Sheet Metal Spinning Company, it is important to compare at least 5 or 6 Suppliers using our list of Sheet Metal Spinning companies. Each Sheet Metal Spinning Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Sheet Metal Spinning company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Sheet Metal Spinning companies with the same message.

Cold Headed Parts

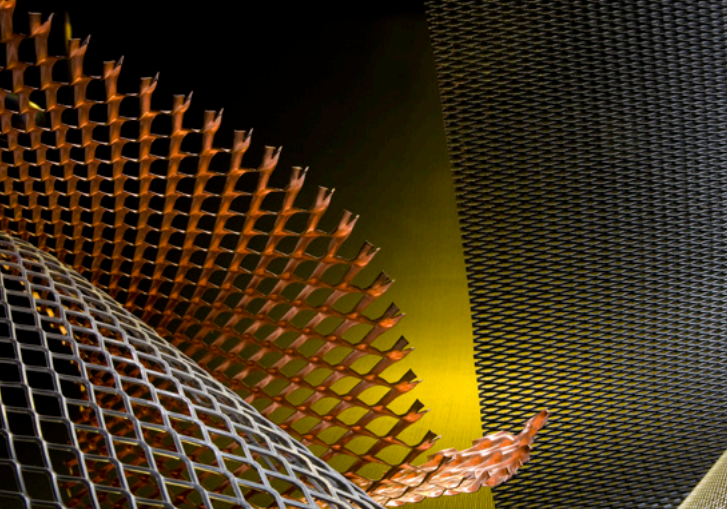

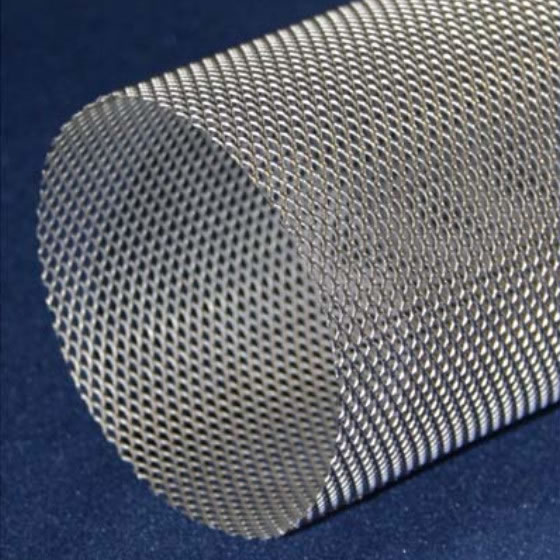

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services