Metal spinning is a cold metalworking process used to shape flat metal discs or tubes (known as blanks) into axially symmetrical parts. This process (which is alternatively called spinning, spin forming or spun metal manufacturing) employs either a hand-operated lathe or a CNC lathe to accomplish this. Read More…

At Ace Metal Spinning, we believe in creating products that precisely meet our customers' specifications. If you need a unique part, we can make it for you. We also provide in-house tooling to keep your costs low. It is our goal to benefit our customers however we can through our service, products, and prices. Learn more on our website today!

Our CNC spinning equipment are fully automated machines and capable of sheet metal spinning, trimming and beading all in one process. Copper spinning and aluminum spinning symmetrically round items is what we do most. Stainless Steel spinning is very popular for the pharmaceutical and food service parts we make. If you need to produce a symmetrical metal part without seams and with minimal...

At Stuecklen Manufacturing Company, we take pride in our long-standing expertise in the art and science of metal spinning. Since our founding, we have dedicated ourselves to combining traditional craftsmanship with modern technology to produce precision-formed components that meet the highest standards of quality and performance.

At Sundry Metal Spinning, we specialize in providing comprehensive solutions for metal spinning, catering to the diverse needs of industries worldwide. With our commitment to excellence and extensive experience, we have established ourselves as a trusted partner for customers seeking high-quality and precise metal spinning services. Our metal spinning capabilities encompass a wide range of...

In business since 1944, Muncie Metal Spinning has been a metal spinning company offering tanks, air cleaners, sump breather tanks, fill cans and much more. In addition, we do custom ornamental metal spinning from aluminum, copper or brass, welding, shearing, and prototype development. Call us today for more information or visit our website and request a quote!

More Metal Spinning Companies

The metal spinning process—also known as spin forming or spinning—plays a pivotal role in modern metal fabrication, offering a versatile and cost-effective method for shaping high-quality, seamless, rotationally symmetric parts. The process involves attaching a metal blank, often made from aluminum, stainless steel, or other ductile metals, to a lathe mandrel and rotating it at high speeds. A skilled metal spinner, or an automated CNC spinning system, then applies pressure using one or multiple form tools to coax the metal into its desired shape. Unlike conventional metal turning, which removes material to create forms, metal spinning shapes the metal through controlled pressure and rotation. This efficient, repeatable process is typically completed in five to ten minutes, making it ideal for both prototyping and large-scale production of custom metal components.

How Metal Spinning Works: Step-by-Step Overview

The metal spinning process is relatively straightforward but requires precision and expertise to achieve optimal results. It begins by mounting a formed block—known as a mandrel or chuck—into the drive section of a lathe. Mandrels are usually crafted from hardened wood or durable metals such as mild steel or aluminum. For projects requiring tight tolerances and high repeatability, metal mandrels are typically preferred, though wood offers a cost-saving alternative for lower-precision work.

Are you comparing manual vs. CNC metal spinning? Lathes, the heart of the process, come in various forms—horizontal or vertical, manually operated, or CNC (Computer Numerical Control)-powered. Modern CNC metal spinning delivers enhanced accuracy, automation, and repeatability for demanding industrial applications.

Once the mandrel is secured, a pre-sized blank—typically a flat disc or circle—gets clamped firmly against it with a pressure pad. This pad, connected to the lathe’s tailstock or footstock, provides critical support along the workpiece’s longitudinal rotary axis to maintain stability during high-speed rotation.

With the assembly ready, the metal spinning process commences as the mandrel and workpiece spin at high velocity. A forming tool or roller—often up to three feet long and crafted from hardened steel or solid brass—applies calculated pressure, causing the malleable metal to flow smoothly over the mandrel’s contours. The mandrel’s external profile dictates the internal shape and dimensions of the finished part. For aluminum, hardened steel tools are preferred, while solid brass tools excel with mild or stainless steel. The most common shaping tools are called “spoons,” though more advanced operations may use rollers or even computer-guided tools. Some spinning tools feature a thin ceramic coating to reduce wear and extend service life—critical for high-volume spinning operations.

Following the initial forming stage, the workpiece typically undergoes trimming and finishing operations. Trimming removes excess material and sharp edges, while finishing polishes surfaces and removes minor imperfections. During finishing, the workpiece may be rotated at speeds up to 1200 RPM, minimizing the force required for a smooth result. Specialized finishing tools, such as the “duck bill”—featuring flat and rounded edges—are used to refine straight and curved surfaces. Lubricants such as wax, tallow, and specialized greases are often applied throughout the process to enhance surface appearance, reduce friction, and facilitate easier removal from the mandrel.

Variations and Advanced Metal Spinning Techniques

While the basic metal spinning process is foundational, several advanced techniques and variations adapt the process for distinct applications, part geometries, and production requirements. Let’s explore some of the most notable:

- For complex or multi-stage workpieces, manufacturers may use a multi-piece block or segmented mandrel, which can be disassembled for easier part removal. In highly intricate shapes, an ice form may be utilized—the ice melts away after spinning, eliminating the need for mechanical removal.

- Forming tools also vary. In many commercial settings, traditional spoons are replaced with rollers mounted on levers. These rollers, which vary in thickness and diameter, are used in both CNC and hand metal spinning to precisely form material down to the mandrel’s profile, enabling the creation of parts with tighter tolerances and more complex curves.

Looking for ways to create more complex or high-performance parts? Consider these process variations:

- Reducing or Necking In: This advanced method accommodates workpieces with reentrant geometries (shapes with inward curves or necks). For exact forms, the workpiece is spun on an eccentrically mounted mandrel, allowing precise control over the final shape. If surface finish and accuracy are less critical, parts may be “spun on air” without a supporting mandrel, providing flexibility for non-critical components.

- Hot Spinning: Adding heat to the spinning process enables forming of thicker, harder, or more challenging metals. A torch or induction heater applies localized heat to the workpiece, allowing seamless shoulders and sharp reductions in diameter with less force. Some blanks are annealed (heated and cooled slowly) prior to spinning, enhancing ductility and workability.

Flow forming is a closely related, advanced metal spinning technique offering even greater control over wall thickness and material properties. Flow forming uses two principal methods—shear spinning and tube spinning—to create lightweight, strong, and dimensionally consistent cylindrical parts.

- Shear spinning: This process forms contoured shapes, conical profiles, and deep-drawn parts by using rollers to apply force over flat blanks on rotating mandrels. Unlike conventional spinning, shear spinning reduces the blank’s wall thickness in proportion to the mandrel angle, enabling production of lightweight, high-strength parts for aerospace, automotive, and defense applications.

- Tube Spinning: Used to produce seamless cylinders and tubes, this method cold-works tubular preforms using rollers and a mandrel. There are two main approaches:

- Forward Flow Forming: Produces closed-end parts by advancing the preform in the same direction as the rollers, with the bottom of the preform positioned atop the mandrel face.

- Reverse Flow Forming: Generates open-ended parts by pushing rollers against a serrated ring at the mandrel’s end, compressing and extruding the metal backwards for precise control over wall thickness and internal geometry.

Are you interested in advanced spinning processes for high-precision parts? Learn more about flow forming and its industrial applications.

Advantages of Metal Spinning over Other Metalworking Methods

Why choose metal spinning over methods like stamping, forging, casting, deep drawing, or press forming? The answer lies in the unique combination of efficiency, cost savings, design flexibility, and superior material properties that metal spinning offers. Here’s an in-depth look at the primary benefits:

- Minimal Material Waste: Metal spinning forms parts by reshaping, not removing, material. This results in far less scrap compared to machining or stamping, reducing raw material costs and environmental impact.

- High Structural Integrity: The spinning process aligns the grain structure of the metal, producing seamless, high-strength components with fewer weak points or weld seams. This makes spun parts ideal for pressure vessels, gas cylinders, and critical aerospace components.

- Fast Turnaround and Simplified Production: Metal spinning typically involves just three main steps—forming, trimming, and finishing—versus the eight or more steps required for press forming. This streamlined workflow enables rapid prototyping and faster delivery for both custom and repeat orders.

- Cost-Efficiency: Tooling costs are significantly lower than with stamping, forging, or die-casting. A single mandrel or chuck can produce multiple part sizes and shapes with minimal retooling, making metal spinning highly economical for both small and medium production runs.

- Flexibility and Customization: The process is well-suited for fabricating custom, one-off prototypes as well as large-scale production. Manufacturers can easily adjust design parameters—such as thickness, diameter, or profile—without the need for expensive new dies or molds.

- Superior Surface Finish: When properly finished, spun parts feature smooth surfaces and fine details. The use of lubricants and specialized tools further enhances surface quality, often eliminating the need for secondary polishing or machining.

Considering a new metal forming project? Contact a reputable metal spinning company to discuss your needs, review sample parts, or request a quote for your application.

Limitations and Challenges of Metal Spinning

While metal spinning offers significant advantages, it is important to be aware of its limitations when selecting the best metalworking process for your application:

- Shape Restrictions: Metal spinning is best suited for producing round, axially symmetric parts such as cylinders, cones, hemispheres, or parabolic shapes. It is not ideal for complex, non-round, or highly detailed geometries.

- Metal Thinning: The spinning process may cause the material to thin as it stretches over the mandrel, especially in deep or complex shapes. This must be carefully controlled to avoid weak spots or part failure.

- Challenging Tolerances: Achieving extremely tight tolerances or intricate details can be more difficult compared to CNC machining or precision stamping. Skilled operators or advanced CNC programming may be required for high-precision work.

- Repair Limitations: If a part becomes cracked or dented during spinning, it is usually not cost-effective to repair. Damaged workpieces are typically scrapped and remade.

- Limited Non-Symmetric Applications: If your design requires deep flanges, sharp corners, or non-symmetric features, alternative forming methods such as hydroforming, deep drawing, or stamping may be more suitable.

Not sure which metal forming process aligns with your requirements? Ask a metal fabrication expert about the best process for your application.

Applications and Industries Served by Metal Spinning

Metal spinning companies serve a broad spectrum of industries, delivering custom parts for both functional and decorative uses. The process is especially valued for its ability to produce strong, lightweight, and seamless components. Below are some of the top applications and industries utilizing metal spinning:

- Aerospace & Defense: Rocket nose cones, pressure vessels, engine parts, missile components, satellite housings, and radar domes—where strength, reliability, and weight savings are critical.

- Medical & Pharmaceutical: Sterile filter housings, medical instrument cases, diagnostic device enclosures, and centrifuge bowls—requiring high precision and hygienic finishes.

- Food Processing & Appliances: Mixing bowls, freezers, gas cylinders, pressure cookers, and specialty cookware—demanding sanitary finishes and durable, corrosion-resistant metals.

- Lighting & Architecture: Custom light reflectors, decorative domes, architectural details, urns, and public waste receptacles—where aesthetic appeal and custom shapes are important.

- Automotive & Transportation: Wheel rims, brake components, fuel tanks, air filter housings, and exhaust system parts—requiring strength, precision, and high-volume production.

- Musical Instruments: Brass instrument bells, drum shells, cymbals, and gongs—where resonance and uniform wall thickness are essential for sound quality.

- Industrial & Commercial: Funnels, hoppers, filter cartridges, ventilation ductwork, and laboratory vessels—used for fluid handling, air management, and process containment.

What types of shapes can be produced through metal spinning? Common geometries include conical (cone-shaped), parabolic (bell-shaped), toroidal (donut-shaped), and Venturi (hourglass-shaped) forms. These rounded metal parts are valued for both practical functionality and aesthetic design. For example, a metal-spun vase serves as both a decorative and utilitarian object.

Material Options for Metal Spinning

Metal spinning is compatible with a wide range of metals and alloys, making it a versatile choice for diverse industries and applications. The most commonly spun metals include:

- Aluminum: Lightweight, corrosion-resistant, and easy to form—ideal for aerospace, lighting, and consumer goods.

- Stainless Steel: Offers superior strength, corrosion resistance, and a clean finish—favored in food processing, medical, and architectural applications.

- Brass & Copper: Highly malleable, with excellent electrical and thermal conductivity—used for decorative, musical, and electrical parts.

- Carbon Steel: Strong and cost-effective, suitable for industrial parts and pressure vessels where corrosion is not a primary concern.

- Nickel Alloys, Titanium, and Specialty Metals: Employed in high-performance, high-temperature, or corrosive environments, such as aerospace, defense, and chemical processing.

Need help choosing the best metal for your spun part? Consult with a metal spinning manufacturer for material recommendations based on your application, required tolerances, and budget.

How to Select a Metal Spinning Service or Supplier

Are you looking to source custom metal spinning services? Here’s what to consider when evaluating potential suppliers to ensure you get the highest-quality parts and the best value:

- Production Capabilities: Does the supplier offer both manual and CNC spinning? Can they handle the size, thickness, and volume your project requires?

- Material Expertise: Are they experienced with your specified metal—whether it’s aluminum, stainless steel, copper, or specialty alloys?

- In-House Tooling and Engineering: In-house design and tooling capabilities reduce lead times and ensure better quality control for custom shapes and profiles.

- Turnaround Times: Typical lead times are 2-3 weeks, but urgent projects may require expedited service. Ask about their capacity for rush orders or prototyping.

- Secondary Services: Many reputable metal spinning companies also offer welding, powder coating, heat treating, anodizing, washing, or assembly—providing a complete, turnkey solution.

- Quality Assurance: Look for suppliers with ISO certification, in-process inspections, and a history of delivering tight-tolerance, defect-free parts.

- Customer Service & Communication: Responsive communication, clear technical support, and willingness to collaborate on design or material selection set top suppliers apart.

Ready to request quotes or compare vendors? Browse our directory of metal spinning companies to find the right partner for your next project.

Frequently Asked Questions About Metal Spinning

- What industries benefit most from metal spinning? Aerospace, defense, medical, lighting, food processing, and musical instrument manufacturers frequently utilize metal spinning for its strength, seamlessness, and cost efficiency.

- Can metal spinning be used for both prototyping and mass production? Yes—its low tooling costs and repeatability make it ideal for both one-off custom parts and high-volume production runs.

- What are typical tolerances achievable with metal spinning? Standard tolerances range from ±0.020″ to ±0.030″, though tighter tolerances are possible with skilled operators or advanced CNC equipment.

- Which metals are best suited for spinning? Ductile metals—aluminum, stainless steel, copper, and brass—are most common, but advanced alloys can also be spun with proper tooling and setup.

- How does metal spinning compare to deep drawing or hydroforming? Metal spinning offers lower tooling costs and greater flexibility for round, symmetric parts, while deep drawing and hydroforming are better for more complex, non-symmetric, or multi-featured geometries.

Have more questions or need a project consultation? Contact our metal spinning experts for personalized advice.

Summary and Next Steps

Metal spinning is a powerful, efficient, and cost-effective metal forming process, producing seamless, high-strength, and visually appealing parts for a wide array of industries. Its advantages include minimal waste, quick setup, flexible design options, and compatibility with both manual and CNC automation. However, like all manufacturing processes, it has its limitations—primarily in terms of shape complexity and thickness control.

If you’re considering metal spinning services for your next project, weigh your options carefully by considering the desired part geometry, material properties, production volume, and finish requirements. Collaborate with experienced suppliers who offer in-house engineering, robust quality control, and responsive customer support to ensure the best results.

Explore our comprehensive directory of metal spinning companies to request quotes, review capabilities, and connect with top manufacturers near you. For more detailed technical guidance, industry insights, or to discuss your specific application, contact our team today.

Cold Headed Parts

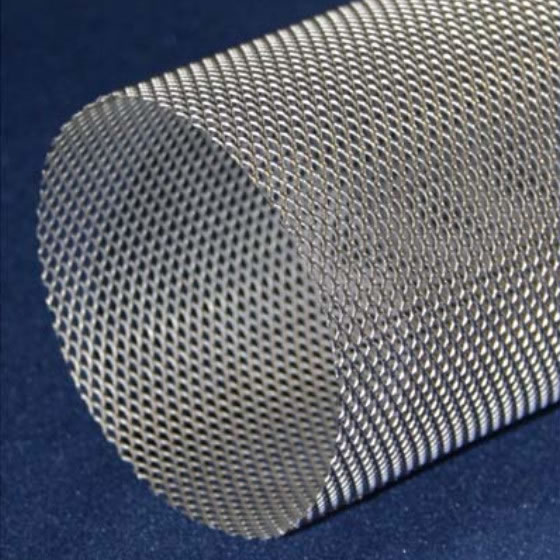

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services