In the metal spinning process, a metal sheet is flattened into a disc and spun around a mandrel to create symmetrical, spherical shapes. Metal spinning creates shapes like hemispheres, cones, dishes, domes, cylinders, and flanges. Stainless steel bowls, satellite dishes, and brass instruments, including trumpets, tubas, cornets, and gas cylinders, are some products made by metal spinning. Read More…

At Ace Metal Spinning, we believe in creating products that precisely meet our customers' specifications. If you need a unique part, we can make it for you. We also provide in-house tooling to keep your costs low. It is our goal to benefit our customers however we can through our service, products, and prices. Learn more on our website today!

Our CNC spinning equipment are fully automated machines and capable of sheet metal spinning, trimming and beading all in one process. Copper spinning and aluminum spinning symmetrically round items is what we do most. Stainless Steel spinning is very popular for the pharmaceutical and food service parts we make. If you need to produce a symmetrical metal part without seams and with minimal...

At Stuecklen Manufacturing Company, we take pride in our long-standing expertise in the art and science of metal spinning. Since our founding, we have dedicated ourselves to combining traditional craftsmanship with modern technology to produce precision-formed components that meet the highest standards of quality and performance.

At Sundry Metal Spinning, we specialize in providing comprehensive solutions for metal spinning, catering to the diverse needs of industries worldwide. With our commitment to excellence and extensive experience, we have established ourselves as a trusted partner for customers seeking high-quality and precise metal spinning services. Our metal spinning capabilities encompass a wide range of...

In business since 1944, Muncie Metal Spinning has been a metal spinning company offering tanks, air cleaners, sump breather tanks, fill cans and much more. In addition, we do custom ornamental metal spinning from aluminum, copper or brass, welding, shearing, and prototype development. Call us today for more information or visit our website and request a quote!

More Metal Spinner Companies

Different Approaches to Metal Spinning

Metal spinning, also known as spin forming or metal turning, is a highly specialized metalworking process used to create axially symmetric parts by rotating a metal disc or tube and shaping it over a mandrel. Metal spinning is widely utilized in industries such as aerospace, automotive, lighting, HVAC, architectural, and more, due to its ability to provide seamless, structurally robust, and cost-effective components. To achieve optimal results in terms of product quality, production speed, and cost, manufacturers use several distinct metal spinning methods. Understanding these approaches is key for buyers and engineers seeking the right solution for their application, whether for rapid prototyping, low-volume runs, or large-scale production.

Computerized Numerical Control (CNC) Metal Spinning

CNC metal spinning leverages advanced automation and precision controls to streamline the metal forming process. In CNC metal spinning, a programmable lathe automates the shaping of metal blanks, ensuring repeatability and tight tolerances across high production volumes. The process begins with the operator mounting the workpiece on the CNC lathe drive, securing it with a pressure pad. Next, the operator programs the specific parameters for the forming process—such as rotational speed, feed rate, and tool path—into the CNC system. Once started, the lathe rotates the workpiece at high speed while specialized tooling presses the metal into the desired shape, conforming exactly to the mold or mandrel profile.

This method is highly favored in modern manufacturing environments for its exceptional efficiency, consistency, and versatility. CNC metal spinning is particularly suitable for parts requiring complex geometries, precise measurements, and superior surface finishes. Common applications include aerospace components, satellite dishes, industrial bell housings, automotive parts, and lighting reflectors. The process is renowned for its affordability in high-volume production, outstanding mechanical properties, enhanced grain structure, and the ability to work with a broad range of metals, including aluminum, stainless steel, copper, brass, titanium, and specialty alloys.

Choosing CNC metal spinning allows manufacturers to reduce labor costs, minimize material waste, and achieve consistent results across hundreds or thousands of units. Its programmable flexibility also makes it ideal for just-in-time manufacturing and quick changeovers between part designs.

Playback Numerical Control (PNC) Metal Spinning

Playback Numerical Control (PNC) metal spinning is a hybrid process that combines manual expertise with the efficiency of automation. The process begins with an operator manually shaping a workpiece using a joystick or control lever on a specialized lathe. The PNC system records every operator movement, capturing the precise tool paths and pressure applied during the forming process. Once the initial piece is completed, the machine can automatically replay the recorded sequence, replicating the operator’s actions to produce identical parts in subsequent cycles.

PNC metal spinning is well-suited for medium to high production volumes where the initial development of a CNC program may not be justified or when custom, one-off parts need to be duplicated. The replay mode ensures that each piece matches the original, maintaining consistency and quality. Industries such as lighting, decorative metalworking, commercial kitchen equipment, and HVAC ductwork often leverage PNC spinning for bespoke designs and rapid turnaround. Advantages of PNC spinning include reduced setup times, lower tooling costs, and the ability to accommodate quick design changes without extensive reprogramming.

Buyers seeking flexibility for prototyping or moderate batch production often find PNC spinning an ideal solution, as it bridges the gap between traditional manual spinning and fully automated CNC processes.

Hand Metal Spinning

Hand metal spinning is the most traditional approach, requiring a high level of skill, dexterity, and experience. In this method, a skilled metal spinner mounts a metal blank onto a spinning lathe and shapes it by applying hand tools—such as spoons, rollers, or burnishing sticks—against the rotating metal. The artisan carefully manipulates the material, guiding it over a mandrel to create the desired form. Hand spinning is especially valuable for crafting custom, low-volume, or prototype parts that require a personalized touch or intricate detailing that may be challenging for automated machinery.

This approach is favored for specialty manufacturing, artistic projects, restoration of heritage components, and one-off industrial parts. While hand metal spinning is more labor-intensive and time-consuming compared to CNC or PNC methods, it offers unmatched versatility for complex contours and small production runs. The process is often used in industries such as fine art, bespoke lighting, musical instrument manufacturing, and specialty scientific equipment. For buyers prioritizing customization, craftsmanship, and flexibility, hand metal spinning remains an indispensable technique.

The Metal Spinning Design Process

To achieve optimal results from metal spinning—whether for industrial, commercial, or artistic purposes—it is crucial to follow a well-structured design process. Proper planning ensures that the final components meet performance, quality, and cost requirements. Below are key steps and considerations in designing for metal spinning:

1. What is the Object’s Function?

Understanding the end use and function of a metal-spun part is fundamental to the design process. Different applications—such as pressure vessels, reflectors, domes, hoppers, or enclosures—impose varying requirements for strength, dimensional accuracy, and surface finish. For example, aerospace and automotive applications may demand lightweight yet robust forms, while architectural and decorative pieces might prioritize visual aesthetics and intricate detailing. Clearly defining the component’s intended function helps guide all subsequent decisions in material selection, geometry, and tolerances.

2. What Material Will Work Best for This Metal Spinning Project?

The choice of material directly impacts manufacturability, cost, mechanical properties, corrosion resistance, and overall performance. Common materials for metal spinning include:

- Aluminum: Lightweight, corrosion-resistant, and easy to form; ideal for aerospace, lighting, and decorative applications.

- Stainless Steel: Offers high strength, excellent corrosion resistance, and durability for food processing, medical, and industrial parts.

- Carbon Steel: Cost-effective for structural components requiring moderate strength.

- Copper and Brass: Preferred for electrical, plumbing, and artistic projects due to their conductivity and workability.

- Titanium and Specialty Alloys: Used for aerospace, medical, and high-performance applications where weight and strength are critical.

Designers and manufacturers should collaborate closely to select the most suitable metal, considering factors such as thickness, forming characteristics, weight, and intended use. Material availability and cost also play significant roles in the decision-making process.

3. Carefully Consider the Diameters

Properly specifying the diameter of the metal blank and the finished part is essential for efficient material usage and achieving the desired properties. Metal spun objects are often rolled into cylindrical or tubular forms. The wall thickness may vary based on the degree of forming and the type of metal used. Generally, larger corner radii reduce material thinning and tool wear, resulting in stronger, longer-lasting components. Conversely, tighter radii can lead to higher stress concentrations, increased risk of cracking, and greater manufacturing complexity. For cost efficiency and part durability, it is advisable to design with generous radii wherever possible.

4. Think About the Dimensions

Accurate planning of all part dimensions—such as height, diameter, wall thickness, and flange size—is critical during the design phase. Even small material savings per component can accumulate into substantial cost reductions in large-scale production. Overly complex or tight dimensional requirements may necessitate additional forming steps, secondary machining, or custom tooling, which can increase lead times and expenses. Designers should balance functional requirements with manufacturability and cost efficiency, often consulting experienced metal spinners for input during the early design stages.

5. Indicate Tolerances

Specifying appropriate tolerances ensures that the final product meets performance needs without incurring unnecessary production costs. In metal spinning, uniform wall thickness is not always required, as the process naturally leads to some variation. However, designers must define acceptable deviations for critical dimensions to guarantee fit and function. Overly tight tolerances can drive up production costs and scrap rates, while loose tolerances may compromise quality or assembly. It is beneficial to identify which features are most critical and adjust tolerances accordingly.

Challenges Faced by Metal Spinning Manufacturers

Despite the many advantages of metal spinning, manufacturers regularly encounter technical and economic challenges that influence production decisions, part design, and supplier selection. Understanding these obstacles helps buyers set realistic expectations and choose the right partners for their projects.

Shape and Size Limitations

Metal spinning excels at producing axially symmetric and concentric shapes—such as cones, cylinders, hemispheres, domes, and parabolic forms. However, the process is less suited to irregular or non-circular geometries. Attempting to spin asymmetrical components can result in uneven wall thickness, excessive material stress, or outright failure. The maximum diameter and depth of a component are also constrained by the available machinery and tooling. Large, deep, or heavy-gauge parts may require specialized equipment, increasing setup costs and lead times. For projects with unique shape requirements, alternative forming methods—such as deep drawing, hydroforming, or stamping—may be more appropriate.

Production Constraints

Manufacturing metal spun components often involves the use of rollers, spoons, and custom mandrels tailored to the specific part geometry. For bespoke or low-volume productions, the cost and time associated with designing and fabricating new tooling can be prohibitive. This reality makes metal spinning particularly cost-effective at higher production volumes, where tooling expenses can be amortized over many parts. For short runs or prototypes, buyers should weigh the trade-offs between tool investment, turnaround time, and per-unit cost. Advances in rapid prototyping and modular tooling are helping to mitigate these challenges, but production constraints remain a key consideration.

Potential for Errors and Defects

Like all metal forming processes, spinning is subject to potential errors and defects, including:

- Dents, cracks, and thinning resulting from excessive forming forces or improper tool alignment

- Surface imperfections, such as scratches or wrinkles, which may require secondary finishing

- Variations in wall thickness or dimensional accuracy due to material inconsistencies or process variables

Repairing defects—especially cracks or structural flaws—is generally not practical or cost-effective. In many cases, defective parts must be scrapped, resulting in material loss and additional expense. To minimize errors, manufacturers often employ rigorous quality control, skilled operators, and, for certain metals, pre-process heat treatment to enhance ductility and formability. Selecting the right material and collaborative design can further reduce the likelihood of manufacturing defects.

Why Choose Metal Spinning? Key Benefits for Buyers and Engineers

Metal spinning offers a unique combination of benefits that make it an attractive choice for a wide variety of applications. When evaluating manufacturing methods, consider the following advantages of metal spinning compared to alternatives like casting, deep drawing, or stamping:

- Cost Efficiency: Lower tooling costs and material waste, especially for medium to large production runs.

- Design Flexibility: Ability to create complex, seamless shapes with custom profiles and features.

- Superior Mechanical Properties: Improved tensile strength and refined grain structure due to cold working and material flow during forming.

- Rapid Prototyping: Fast turnaround for initial samples or short production runs, enabling quick design validation.

- Enhanced Surface Finish: High-quality finishes suitable for visible or decorative parts, reducing the need for secondary polishing.

- Material Versatility: Compatible with a wide range of metals and alloys, allowing for tailored properties and performance.

- Scalability: Efficient for both small batches and mass production, with easy adaptation to evolving design requirements.

These benefits make metal spinning a popular manufacturing technique for industries seeking quality, reliability, and value across a spectrum of products.

Common Applications and Use Cases for Metal Spinning

Wondering where metal spinning is most effective? The process serves a broad range of industries and end-use scenarios, including:

- Aerospace: Jet engine components, nose cones, satellite dishes, and radomes where strength-to-weight ratio and precision are essential.

- Automotive: Hubcaps, air intake housings, exhaust components, and custom wheels requiring durability and aerodynamic performance.

- Lighting: Reflectors, lamp housings, and decorative fixtures benefiting from seamless construction and aesthetic appeal.

- HVAC: Ductwork, diffusers, and vent hoods designed for airflow efficiency and corrosion resistance.

- Medical: Surgical instrument housings, centrifuge bowls, and laboratory equipment demanding hygiene and dimensional accuracy.

- Architectural: Domes, decorative finials, and custom art installations where bespoke shapes and finishes are desired.

- Food Processing: Bowls, containers, and enclosures that require sanitary, easy-to-clean surfaces.

- Industrial: Pressure vessels, tanks, flanges, and machine covers engineered for strength and reliability.

Buyers across these industries value metal spinning for its adaptability, speed, and ability to deliver high-quality, functional components.

Key Factors When Selecting a Metal Spinning Supplier

How do you choose the best metal spinning company for your needs? Making the right supplier choice is critical to the success of your project, affecting quality, cost, lead time, and long-term reliability. Here are the main decision factors to consider:

- Technical Expertise: Look for suppliers with proven experience in your target industry and material types, as well as advanced equipment for CNC, PNC, and hand spinning.

- Quality Assurance: Ask about the supplier’s quality control processes, certifications (such as ISO 9001), and history of on-time delivery.

- Custom Capabilities: Evaluate whether the manufacturer can handle custom shapes, prototypes, and complex assemblies as needed.

- Production Capacity: Ensure the supplier can scale output to meet your volume requirements, from short runs to mass production.

- Lead Times and Responsiveness: Fast turnaround and clear communication are especially important for time-sensitive projects.

- Value-Added Services: Some companies offer additional services such as secondary machining, finishing, welding, and assembly for one-stop solutions.

- Cost Structure: Request detailed quotes and compare pricing on tooling, setup, and per-unit production to make informed decisions.

Choosing the Right Metal Spinners Supplier

To make sure you have the most constructive outcome when purchasing Metal Spinners from a Metal Spinners Company, it is important to compare at least 5 Manufacturers using our list of Metal Spinners companies. Each Metal Spinners Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Metal Spinners business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Metal Spinners companies with the same quote.

Taking the time to assess multiple suppliers enables you to compare capabilities, pricing, production schedules, and quality standards. Look for companies with a proven track record in your application area—whether that’s aerospace, automotive, industrial, or decorative work. Be sure to clarify your requirements for material type, part geometry, tolerances, and finishing needs. The most reliable suppliers will offer guidance on design optimization, suggest cost-saving opportunities, and maintain transparent communication throughout the project lifecycle. By leveraging a comprehensive supplier comparison process, you can secure the best value and performance for your metal spinning needs.

Frequently Asked Questions About Metal Spinning

What is the difference between metal spinning and deep drawing?

Metal spinning is a process where a flat metal blank is rotated on a lathe and formed over a mandrel using pressure from a tool, resulting in seamless, axially symmetric parts. Deep drawing, on the other hand, involves stretching a sheet metal blank into a die cavity using a punch, often with more complex tooling and higher setup costs. Metal spinning is typically more cost-effective for medium to large cylindrical parts with variable wall thickness, while deep drawing is better for large quantities of shallow, cup-like components.

Which metals are best suited for spinning?

Metals with good ductility and formability are ideal for spinning, such as aluminum, copper, brass, mild steel, stainless steel, and certain alloys. The choice of metal depends on the application’s need for strength, corrosion resistance, weight, and cost. Aerospace and high-performance applications may call for titanium or specialty alloys, while decorative or artistic projects often use softer metals like brass or copper.

How do I determine if my part can be made by metal spinning?

Parts that are axially symmetric—such as cones, cylinders, domes, and parabolic shapes—are strong candidates for metal spinning. If your design requires seamless construction, smooth curves, or complex profiles, metal spinning is likely suitable. Sharing your part drawings and performance requirements with a skilled metal spinner is the best way to confirm manufacturability and optimize the design for cost and performance.

What are typical lead times for metal spun parts?

Lead times can vary depending on part complexity, production volume, material availability, and the supplier’s workload. Prototypes and small batches may be produced within 1–3 weeks, while larger or more complex orders could take 4–8 weeks or longer. Early engagement with your supplier and clear communication of project requirements can help streamline scheduling and minimize delays.

How can I reduce costs in metal spinning projects?

To achieve the best value, consider simplifying part geometry, using standard materials and thicknesses, specifying reasonable tolerances, and selecting experienced suppliers with efficient production methods. Larger batch sizes typically reduce per-unit costs by spreading tooling and setup expenses across more parts. Collaboration between designers and manufacturers in the early stages can also identify cost-saving opportunities without sacrificing quality.

Conclusion: Unlock the Potential of Metal Spinning

Metal spinning remains a cornerstone manufacturing method in industries ranging from aerospace and automotive to architecture and fine art. By understanding the various approaches—CNC, PNC, and hand spinning—alongside the design, material, and supplier considerations, buyers and engineers can make informed decisions that maximize product quality, performance, and value. Whether you need rapid prototyping, high-volume production, or custom, artisan-crafted components, metal spinning offers unmatched versatility, efficiency, and strength. Carefully evaluating your project’s requirements and leveraging the expertise of reputable metal spinning suppliers ensures successful outcomes and long-term satisfaction.

Cold Headed Parts

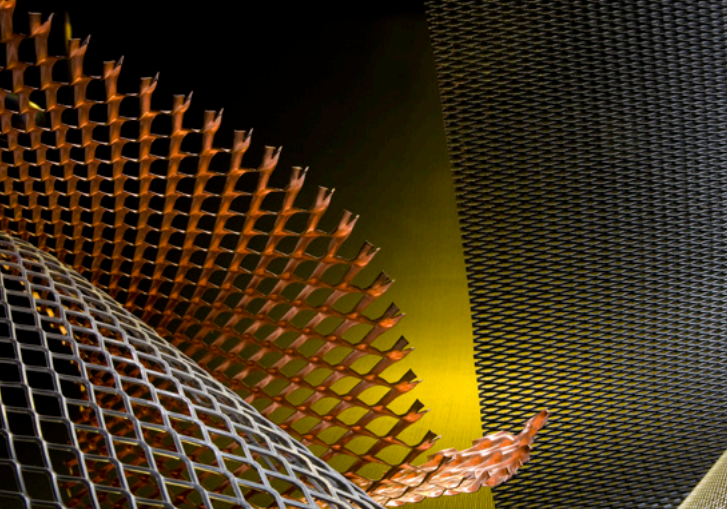

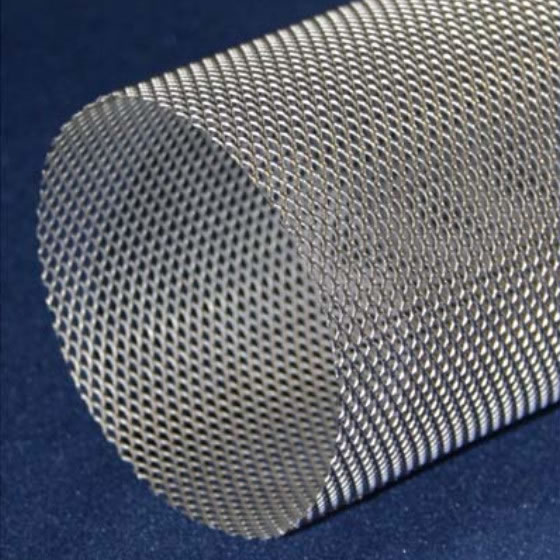

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services