Metal spinning is just one of many metalworking processes used to create specially shaped metal products, but it is chosen above other processes because of its capacity for producing very high quality metal shapes. Read More…

At Ace Metal Spinning, we believe in creating products that precisely meet our customers' specifications. If you need a unique part, we can make it for you. We also provide in-house tooling to keep your costs low. It is our goal to benefit our customers however we can through our service, products, and prices. Learn more on our website today!

Our CNC spinning equipment are fully automated machines and capable of sheet metal spinning, trimming and beading all in one process. Copper spinning and aluminum spinning symmetrically round items is what we do most. Stainless Steel spinning is very popular for the pharmaceutical and food service parts we make. If you need to produce a symmetrical metal part without seams and with minimal...

At Stuecklen Manufacturing Company, we take pride in our long-standing expertise in the art and science of metal spinning. Since our founding, we have dedicated ourselves to combining traditional craftsmanship with modern technology to produce precision-formed components that meet the highest standards of quality and performance.

At Sundry Metal Spinning, we specialize in providing comprehensive solutions for metal spinning, catering to the diverse needs of industries worldwide. With our commitment to excellence and extensive experience, we have established ourselves as a trusted partner for customers seeking high-quality and precise metal spinning services. Our metal spinning capabilities encompass a wide range of...

In business since 1944, Muncie Metal Spinning has been a metal spinning company offering tanks, air cleaners, sump breather tanks, fill cans and much more. In addition, we do custom ornamental metal spinning from aluminum, copper or brass, welding, shearing, and prototype development. Call us today for more information or visit our website and request a quote!

More Aluminum Spinning Companies

Metal spinning produces axially symmetric, round metal shapes that are used in many ways in all kinds of contexts. Just a few spun metal products include rocket nose cones, bowls, architectural lighting components, ash trays, bird baths, furniture, waste receptacles and decorations like candle holders and trophies. Aluminum in particular is valued because of its strength and durability as well as its clean, shiny appearance.

Also, because metal spinning is a cold working process, spun aluminum products are usually particularly strong, especially compared to products of hot working processes. Although aluminum metal spinning can be controlled by hand, computer numerical controlled metal spinners are more commonly used; CNC machines can produce very precise and defect-free products much more quickly than can manual metal spinner operators. CNC machines also ensure quality and consistency from part to part. When the forming of the part is controlled by hand, it can be a physically demanding process, requiring a great deal of practice.

Metal spinning is a fairly simple process on a conceptual level. It is a cold working process, which means that the metal shaping takes place at or near room temperature. Many other metalworking processes are performed at very high temperatures. Metals become easier to shape at very high temperatures, but the increased risk of oxidation and other undesirable consequences make hot working impractical in the formation of some kinds of metal products.

Metal spinning involves a lathe, shaping tools and the metal material for spinning. This material is called a blank, and it is usually a flat round disc made of aluminum, copper, stainless steel or another metal. The blank is attached to the lathe, which spins around at high speeds in order to expose the entire blank to the shaping tools.

The shaping tools then apply pressure in the appropriate places, shaping the metal as it spins. This pressure can be applied by a single tool or by multiple levers hydraulically. The finished aluminum product, if produced correctly, should have no wrinkling or warble due to the high speed of rotation on the lathe. The process is cost-effective and quick, with the average aluminum piece only requiring about five to ten minutes to complete.

Cold Headed Parts

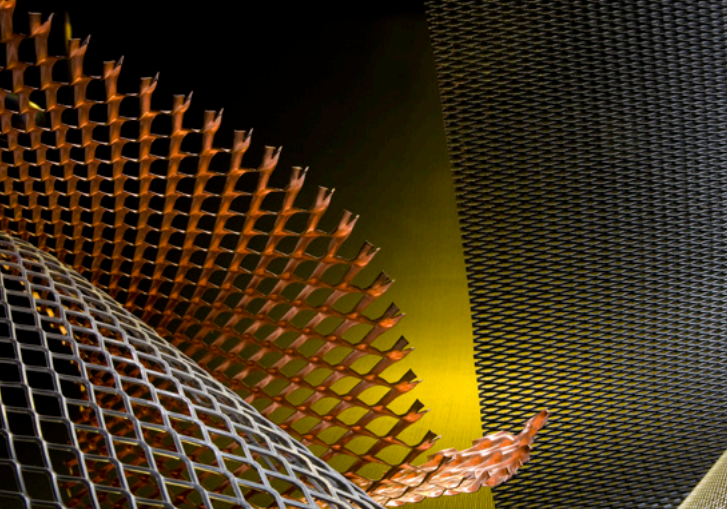

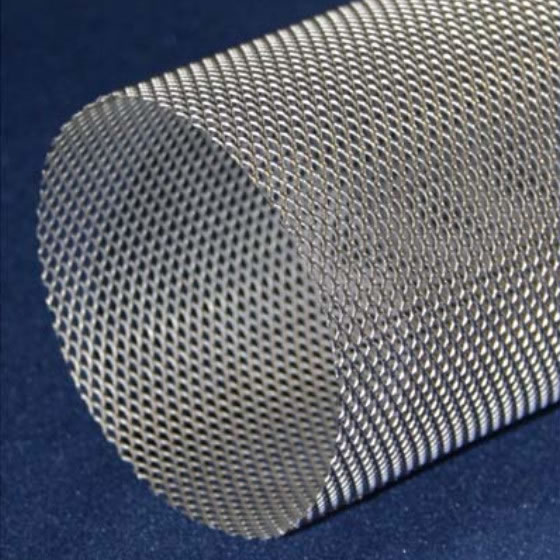

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services