Metal spinning can be done manually or it can be automated with the use of CNC machinery. Manual metal spinning requires a highly skilled technician to operate the lathe. A flat metal disc, also referred to as a blank, is affixed to a lathe mandrel and rotated. The metal is then shaped with hand-held tools as the metal spinner technician applies pressure to the blank. In the end, there should be little to no metal waste and no wrinkling and both the interior and exterior surface of the product should be smooth and shiny.

Generally, metal spinning is a cost-effective choice for companies. It is typically used for smaller runs. Metal spinning produces hollow, symmetrical shapes maintaining a wall thickness throughout the piece. Metal spinning processes like hydroforming and shear spinning provide alternative ways to shape metal with a cold metalworking process.

Metals that can be used for metal spinning include steel, stainless steel, aluminum, copper titanium, and alloys of these metals. Metal spinning adds to the excellent characteristics of these metals and alloys such as their hardness, strength and durability.

Cold Headed Parts

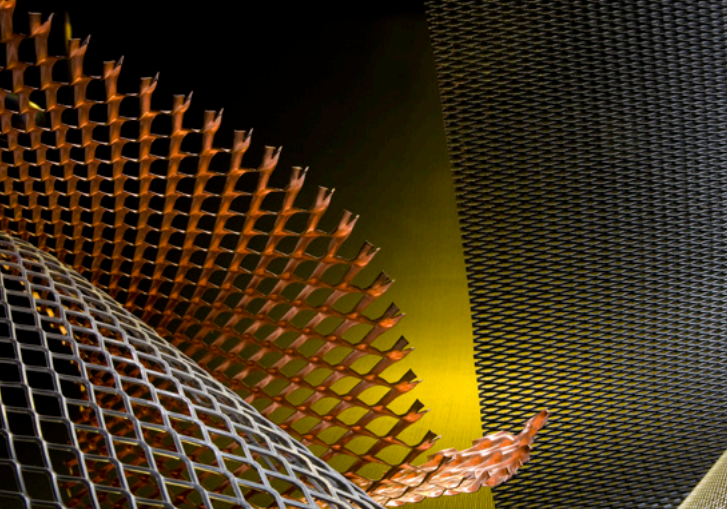

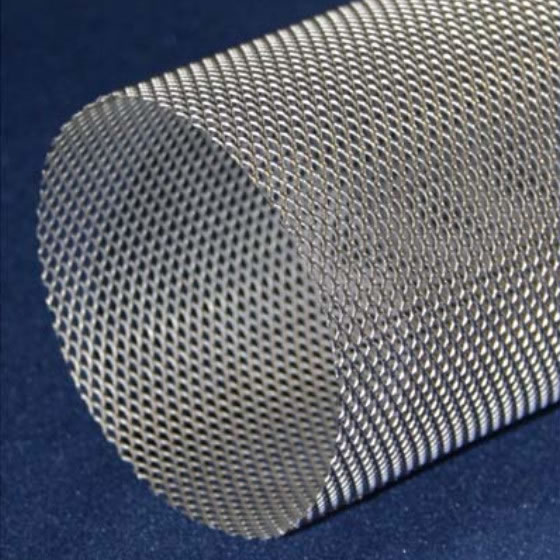

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services