Explore Our Hydroforming Gallery

Welcome to our Hydroforming Gallery! Here, you can explore a range of high-performance hydroforming manufacturers. Each category showcases precision hydroforming processes used in various industries, ensuring top-quality products for diverse applications.

Hydroforming – Acme Metal Spinning Inc.

Hydroforming – Acme Metal Spinning Inc.

Hydroforming – Lansco Manufacturing Services

Hydroforming – Lansco Manufacturing Services

Hydroforming – Lansco Manufacturing Services

Hydroforming – Lansco Manufacturing Services

Overview of Hydroforming

Hydroforming is a manufacturing process that uses high-pressure hydraulic fluid to shape malleable metals into complex shapes. This technique is widely used for producing parts that require strength and precision. Hydroforming delivers enhanced product consistency, reduced material waste, and improved design flexibility for a wide range of applications.

Types of Hydroforming and Their Applications

Hydroforming can be classified into two main types: tube hydroforming and sheet hydroforming. Tube hydroforming is used to shape tubular structures for automotive and aerospace industries, while sheet hydroforming is commonly employed to create complex shapes for products such as body panels and structural components. Each type serves distinct purposes in improving product durability and functionality.

Industries Served by Hydroforming

Hydroforming serves a wide range of industries, including automotive, aerospace, medical devices, and industrial equipment. In the automotive industry, it is commonly used to create lightweight, high-strength components that enhance performance and fuel efficiency. Aerospace manufacturers use hydroforming to produce parts that meet strict quality standards and withstand high stresses.

Benefits of Choosing the Right Hydroforming Manufacturer

Selecting the right hydroforming manufacturer is crucial for ensuring the production of high-quality, cost-effective parts. Experienced manufacturers employ advanced techniques to deliver precision, consistency, and efficiency in production. By choosing a reliable supplier, companies can minimize production costs and reduce lead times while maintaining high standards of product integrity.

Discover More Industry-Leading Suppliers

Need more options? Explore IQS Directory to find the most trusted manufacturers and suppliers in the industry.

Cold Headed Parts

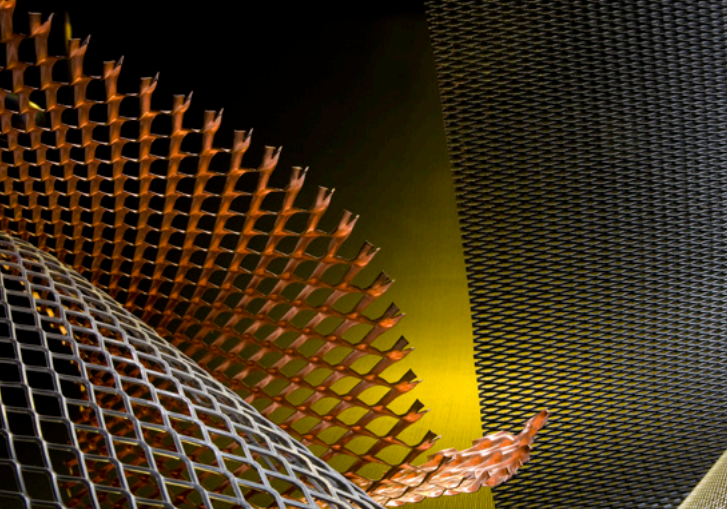

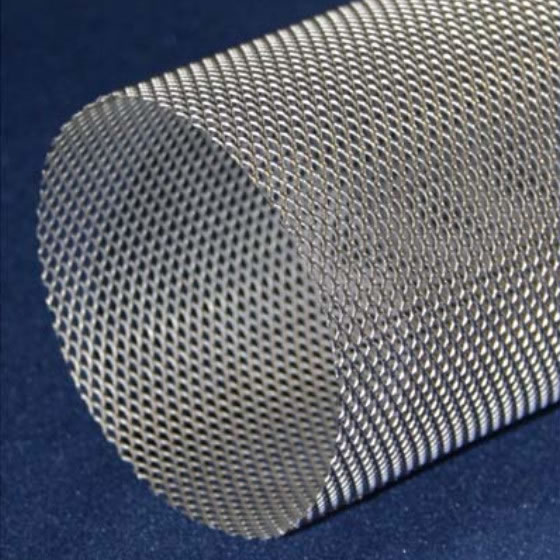

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services